CORROSION

What is corrosion? Corrosion (irreversible process) is a natural process in which pure

metal (unstable) except noble metals is converted into chemically stable compounds like oxides, sulphide, hydroxide, carbonates etc. or The process of slowly deterioration of the metal due to attack of atmospheric gases on the surface of metal resulting into the

formation of more stable compounds such as oxides, sulphide, carbonates etc. is known

as Corrosion. The most common corrosion is rusting of Iron (Fe2O3.xH2O).

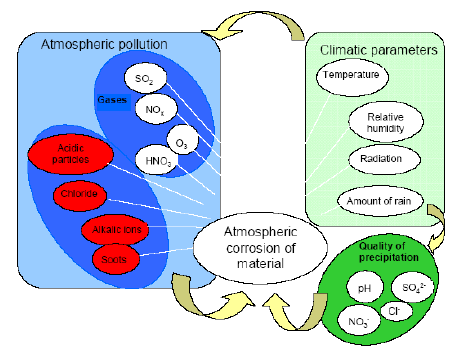

2. Factor affecting Corrosion

a) Reactivity of metal:

If metal is more reactive then it undergoes corrosion more readily.

b) Strain in metal:

Corrosion takes place readily at cuts and bends area of metal.

c) Presence of impurities:

If impurities present in the pure metal then metal undergoes corrosion more readily.

d) Presence of electrolyte:

In saline water (electrolyte) metal readily corrodes.

e) Air and moisture:

Best example rusting of Iron.

f) pH:

pH< 7 is more corrosive than basic or neutral medium.

g) Temperature:

At higher temperature rate of corrosion become increased.

3. Electrochemical theory of corrosion (Wet theory of Corrosion)

When metals are exposed to air, moisture, soil etc. then they undergoes corrosion

through electrochemical process. In this process a separate anode and cathode areas

are form on the metal surface. Corrosion always occurs at the anodic areas of metal

through oxidation reaction and release electron. The liberated electron from anode,

move towards cathode, where reduction take place. The overall theory is known as electrochemical theory of corrosion. It is also known as Wet theory of corrosion

because corrosion takes place in presence of moisture. The flow of free electrons in

this corrosion takes place through following processes:

a) Hydrogen Liberation

b) Absorption of Oxygen

a) Hydrogen Liberation:

This type of corrosion evolution of hydrogen occurs in acidic medium. Let’s

considering the metal Fe, anodic reaction is dissolution of iron as ferrous ions with

Liberation of electrons.

b) Absorption of Oxygen:

The rusting of iron takes place in neutral aqueous solution of electrolytes (presence of

atmospheric oxygen). If the metal surface develops cracks, anodic areas are created

on the surface whereas the metal parts act as cathodes.

7. Corrosion Prevention

a) Metal Coating

In order to protect base metal form corrosion metal coating process has been adopted.

The coating of metal can be achieved by following processes.

i) Anodic metal coating (Galvanization):

Metal coating which is anodic to base metal, known as anodic metal coating. In

order to protect a metal from corrosion, any metal (anodic in nature) which is

higher in the galvanic series like Zn is coated on the surface of metal (base

metal/ cathodic in nature).

ii) Cathodic metal coating (Tinning):

Metal coating which is cathodic to base metal, known as cathodic metal

coating. In order to protect a metal from corrosion, any metal (cathodic in

nature) which is lower in the galvanic series like Sn, Cu, Ni etc, are coated on

the surface of metal (base metal/ anodic in nature).

d) Electroplating:

In electroplating, electro-deposition of metal (anode) by means electrolysis over

surface of metals and alloys (cathode or base metal). The two electrodes are dipped in

the electrolyte solution which contains the metal ions to be deposited on the base

metal. When a direct current is passed from an external source, the coating metal ions

migrate towards cathode and get deposited over the surface of base metal in the form

of a thin layer. In electroplating metal like Au, Ag, Zn, Sn, Cr, Ni etc. can be placed

on the surface of base metal (Cathode).